How CoreMorrow Piezo Scanner Unlocks Confocal Microscopes' Nanoscale Imaging

Confocal microscopy has become an important exploration and research tool in the fields of life sciences, materials research and semiconductor detection mainly due to its 3D tomography imaging capability and the feature of achieving subcellular resolution. Confocal microscopy enables researchers to disassemble the microscopic world layer by layer. With the assistance of piezo objective scanners, this disassembly becomes more precise, faster and more reliable. From cell dynamics to material defects, from basic research to industrial inspection, it continuously expands the boundaries of microscopic exploration.

(Note: Image from online resources)

I. Confocal Microscopic Imaging

A Powerful Tool for Building 3D Images

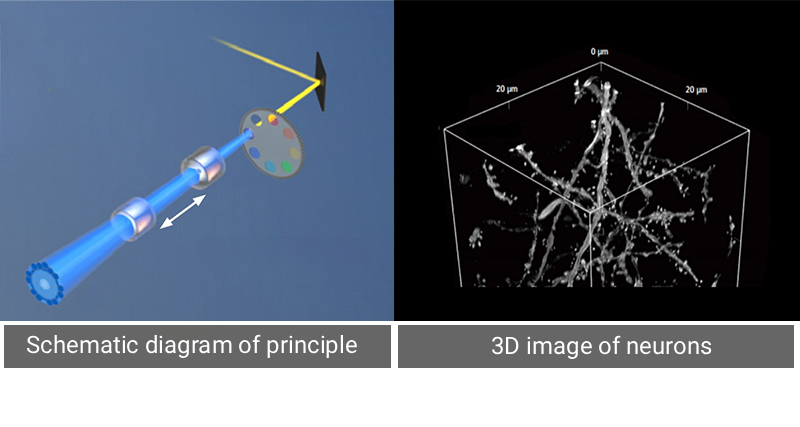

The imaging principle of confocal microscopy is based on laser scanning and optical sectioning technology. By using a focused laser beam, the microscope can scan the sample point by point and eliminate defocused light through the pinhole aperture effect, thereby achieving high-resolution 2D images. In addition, through layer-by-layer scanning, confocal microscopy can also construct the 3D morphology of the sample.

(Note: Image from online resources)

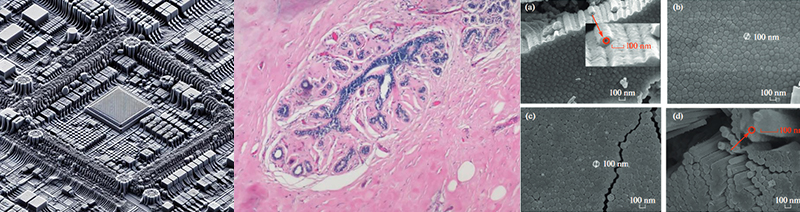

Confocal microscopy can be widely used: in the semiconductor field, it can clearly present the internal structure of semiconductor chips and detect nanoscale defects; In the medical field, it can scan pathological sections and precisely locate the distribution of diseased cells. In materials science, it is possible to observe the structural characteristics of the material surface. In a total, confocal microscopic imaging technology is the standard tool for microscopic 3D imaging.

(Note: Image from online resources)

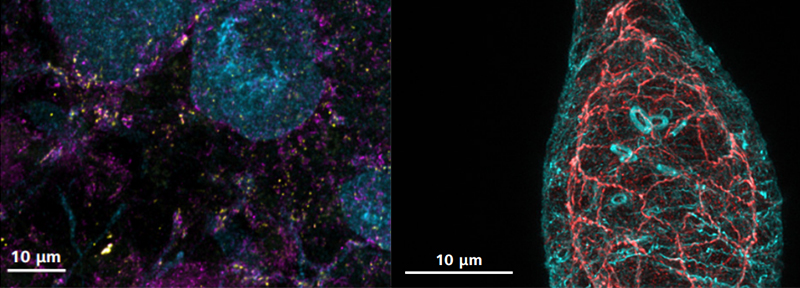

The core advantage of confocal microscopy imaging technology lies in its resolution. The lateral resolution of confocal microscopes can be up to sub-micron level, while the axial resolution is even higher, usually at the nanometer level. This high resolution enables confocal microscopes to capture the minute changes and details on the material surface, clearly presenting the morphological details of tiny objects.

(Note: Image from online resources)

II. CoreMorrow Piezo Objective Scanner

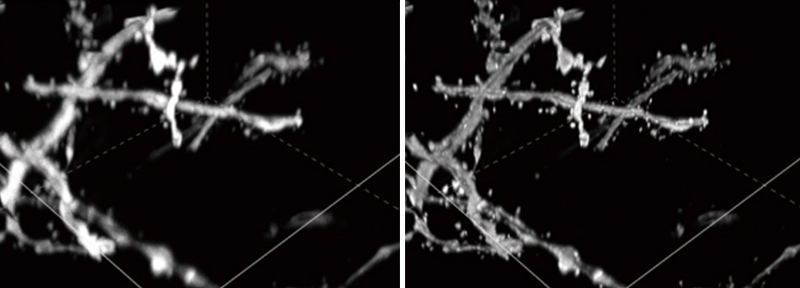

The efficiency and accuracy of confocal imaging directly depend on the response time and repeat positioning accuracy of the objective scanners: a slow response speed can cause imaging delay, especially when scanning live samples, which may lead to image distortion due to cell activity. Inaccurate positioning may lead to slice misalignment and deviations in 3D reconstruction.

(Note: Image from online resources)

CoreMorrow piezo objective scanner is compact in size and easy to integrate into the objective lens turntable or tube. It features high positioning accuracy and fast response speed, which can assist the objective lens in precise positioning. Meanwhile, the integrated design can reduce external vibration interference and avoid imaging blurring caused by minor displacements. It can also ensure that the positions of the sliced samples are precisely aligned, and the final reconstructed 3D image is free of distortion and tomography.

Core Technological Advantages

Nanometer-level precision: The closed-loop positioning accuracy is extremely high, meeting the requirements of super-resolution imaging.

Millisecond-level response: Millisecond-level response time, suitable for building dynamic models of living cells.

High load capacity: It can flexibly adapt to different objective lens requirements and perform high-speed and precise movements under high loads.

Focusing stability: The flexible hinge parallel guiding mechanism design ensures no friction, with a small objective lens compensation amount, and features extremely high focusing stability.

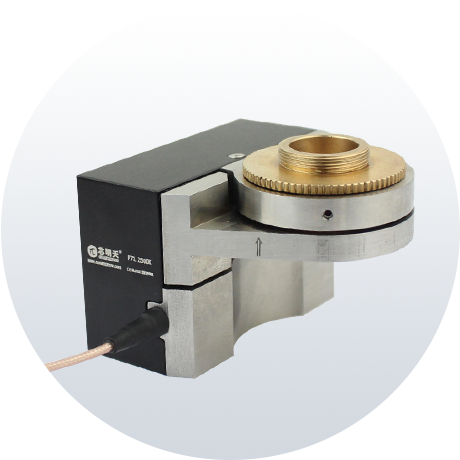

P76 Large-load Piezo Objective Scanner

P76 series piezo objective scanner features a large load capacity up to 900g, Z-axis linear motion range from 40 to 200μm, adopting flexible hinge mechanism, no friction, good linearity, high closed-loop positioning accuracy.The detachable threaded adapter design makes it compatible with various models of microscopes.

Characteristics

• Travel to 200μm

• Load capacity to 900g

• Millisecond response time

• Closed loop for high repeatability

• Excellent focusing stability

Typical Model

|

Model |

P76.Z100S |

|---|---|

|

Active axis |

Z |

|

Drive control |

1 driving channel, 1 sensing channel |

|

Nominal travel range (0~120V) |

80μm |

|

Max. travel range(0~150V) |

100μm |

|

Sensor |

SGS |

|

Resolution |

1nm |

|

Closed-loop linearity |

0.03%F.S. |

|

Closed-loop Repeatability |

0.02%F.S. |

|

Push/pull force |

70N/10N |

|

Stiffness |

0.8N/μm |

|

Unloaded resonant frequenc |

800Hz |

|

Closed-loop operating frequency (-3dB) |

160Hz (Unloaded) |

|

Closed-loop unloaded step time |

5ms |

|

Load capacity |

0.5kg |

|

El. capacitance |

7.2μF |

|

Material |

Steel, Al |

|

Mass |

500g |

P73 Large-load Piezo Objective Scanner

P73 piezo objective scanner features a long travel of 200μm, 500μm or 1mm in Z direction. It adopts a detachable thread adapter design, with multiple thread teeth to choose from, and can be adapted to various types of microscopes. P73 is widely used in long-travel scanning of microscopic imaging, two-photon microscopy and other fields.

Characteristics

• Optional 200μm, 500μm or 1mm travel

• Load capacity to 900g

• Millisecond response time

• Closed loop for high repeatability

• Excellent focusing stability

Typical Model

|

Model |

P73.Z500S-C |

|---|---|

|

Active axis |

Z |

|

Drive control |

1 driving channel, 1 sensing channel |

|

Nominal travel range (0~120V) |

400μm |

|

Max. travel range(0~150V) |

500μm |

|

Sensor |

SGS |

|

Resolution |

14nm |

|

Closed-loop Repeatability |

0.05%F.S. |

|

Push/pull force |

80N/10N |

|

Stiffness |

0.2N/μm |

|

Unloaded resonant frequency |

170Hz |

|

Closed-loop unloaded step time |

120ms@200g |

|

Load capacity |

0.4kg |

|

El. capacitance |

14μF |

|

Material |

Steel,Al |

|

Mass |

300g |

P75 Large-load Piezo Objective Scanner

The P75 piezo objective scanner can achieve a displacement of 250μm in the Z-axis direction and has a load capacity up to 0.2kg. It adopts a frictionless flexible hinge parallel guiding mechanism, with no friction, good linearity and high positioning accuracy, low compensation amount of objective lens , with ultra-high focusing stability. It has a design of separated thread adapterr ,which make it able to adapt to various models of microscopes.

Characteristics

• Max. travel range to 250μm

• Load capacity to 0.2kg

• Design of separated thread adapter

• High closed-loop repeatability

Typical Model

|

Model |

P75.Z200S |

|---|---|

|

Active axis |

Z |

|

Drive control |

1 driving channel, 1 sensing channel |

|

Nominal travel range (0~120V) |

200µm |

|

Max. travel range(0~150V) |

250µm |

|

Sensor |

SGS |

|

Resolution |

6nm |

|

Closed-loop Repeatability |

0.05%F.S. |

|

Push/pull force |

25N/10N |

|

Stiffness |

0.1N/μm |

|

Unloaded resonant frequency |

389Hz |

|

Closed-loop operating frequency(-3dB) |

20Hz |

|

Closed-loop unloaded step time |

25ms@200g |

|

Load capacity |

0.2kg |

|

El. capacitance |

6.5μF |

|

Material |

Steel, Al |

|

Mass |

225g |

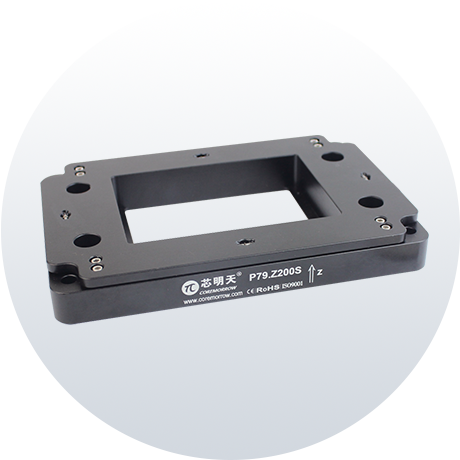

P79 Lrge-load Piezo Nano-positioning Platform

P79 is a 1-3 axes micro-motion platform, mainly used for supporting macro-motion XY-axes micro-scanning stages. After the macro-motion XY-axes positions the sample, P79 platform can perform fast Z-axis focus adjustments with milliseconds step time.

Characteristics

• 50 to 200μm travel for choice

• Large aperture

• Z or XYZ version

• Load capacity to 2kg

• High closed-loop repeatability

• UHV version available

Typical Model

|

Model |

P79.Z200S86-D |

|---|---|

|

Active axis |

Z |

|

Drive control |

1 driving channel, 1 sensing channel |

|

Nominal travel range (0~120V) |

160µm |

|

Max. travel range(0~150V) |

200µm |

|

Sensor |

SGS |

|

Aperture |

86.5mm×128.5mm |

|

Closed-loop resolution |

6nm |

|

Closed-loop Repeatability |

0.1%F.S. |

|

Picth/yaw/roll |

<20µrad |

|

Stiffness |

0.2N/µm |

|

Unloaded resonant frequency |

100Hz |

|

Load capacity |

1.5Kg |

|

El. capacitance |

21.6μF |

|

Working temperature |

-20°C~80°C |

|

Material |

Steel,Al |

|

Mass |

770g |

For further details, please call +86-451-86268790, or add WeChat ID: 17051647888.

- Previous article:No more

- Next article:E53.D2E-K Handheld Piezo Controller Brings More Convenient Operation