P11 Piezo Stage for Hyperspectral Thermal Reflectance Imaging

In high-end fields such as semiconductors, new materials, and biomedicine, with the leapfrog improvement in chip performance and the rapid replacement of material compositions, high-precision non-destructive testing has long been the key to technological breakthroughs. Hyperspectral frequency-domain thermal reflection imaging technology, as a detection solution that combines thermal physical property measurement and multi-dimensional imaging, is gradually becoming an essential technology in both scientific research and industrial mass production. However, as a cutting-edge technology for characterizing the thermal physical properties of materials, hyperspectral frequency-domain thermal reflection imaging still requires a core precision guarantee to support it - that is, the piezo nano-positioning stage. CoreMorrow P11.XYZ100 piezo nano positioning stage is specially designed for high-precision and cutting-edge applications, focusing on enhancing the accuracy and stability of advanced detection technologies.

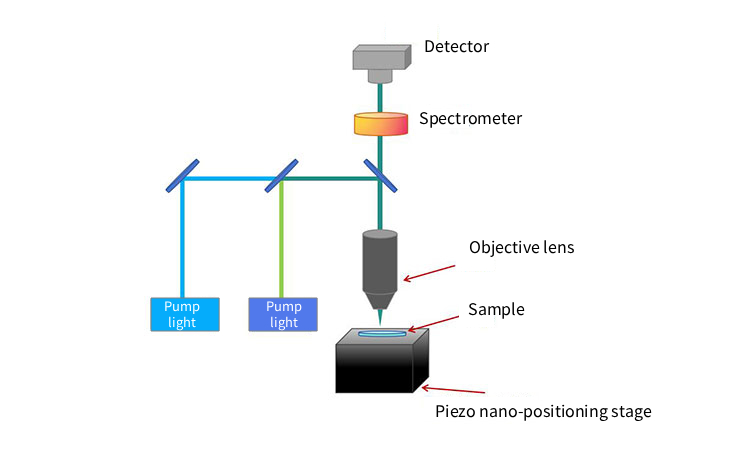

I. The Principle of Hyperspectral Frequency-Domain Thermal Reflection Imaging System

Hyperspectral frequency-domain thermal reflection imaging is a non-contact optical measurement technology with high spatial resolution. In simple terms, it is an advanced optical thermal CT imaging technology that integrates three analytical methods: thermal physical property detection, spectral analysis, and imaging technology. The basic principle is as follows: Firstly, a pump laser beam with intensity modulation is used to irradiate the surface of the sample to achieve a periodic temperature change effect. Meanwhile, another wide-spectrum detection light beam is used to sense the changes in reflectance on the sample surface caused by temperature variations. By analyzing the phase and amplitude delay of the detection light reflection signal relative to the pump light, thermal information at different depths within the material can also be obtained. In addition, it is different from traditional single-wavelength technology, it can collect hundreds of signals at different wavelengths and frequencies at one time. By leveraging the rich spectral information, it can more accurately calculate the thermal physical parameters, geometric structure forms or internal defects of the tested samples, and present them in a multi-dimensional imaging manner.

Diagram of hyperspectral frequency-domain thermal reflection imaging system

The core advantage of hyperspectral frequency-domain thermal reflection imaging lies in its non-contact and non-destructive detection characteristics, as well as its spatial resolution at the micrometer or even sub-micrometer level. It can simultaneously obtain spectral information, thermal physical property information, and spatial structure information, breaking through the limitations of traditional detection technologies in terms of precision shortage and single information.

II.Application Fields of Hyperspectral Frequency-domain Thermal Reflection Imaging Systems

The core measurement value of the hyperspectral frequency-domain thermal reflection imaging system is multi-dimensional, high-precision, and non-destructive acquisition of key information about materials, which covers the core inspection requirements of multiple industries:

1.

New material research and development: Measuring the thermal conductivity and thermal diffusivity of nanofilms, detecting internal defects in composite materials, and evaluating the thermal properties of 2D materials (such as graphene, etc.);

2.

Semiconductor chips: Precisely locate the thermal distribution of transistors inside the chip, measure the thermal conductivity of semiconductor films, evaluate the thermal physical properties of the microstructure of electrical components, etc.

3.

Biomedical: Detecting the thermal conductivity differences between normal and abnormal tissues, the thermal conductivity performance of artificial skin and tissue-engineered scaffolds, and the subtle thermal changes during cell metabolism, etc.

4.

High-end industrial manufacturing: Testing the thermal uniformity of automotive power battery packs, the thermal reliability of engine core components, the thermal conductivity of thermal protective coatings for spacecraft, etc.

Note: Image from online resources

III. CoreMorrow Piezo Nano-positioning Stage is used to Ensure Measurement Accuracy

P11 is a small-volume 1~3 axes piezo nanopositioning stage. It adopts a no-friction flexible hinge guiding mechanism and amplified-drive mechanism to ensure 100μm displacement. Closed-loop version could achieve positioning accuracy up to nano-scale. It features excellent control precision, high rigidity, high load capacity, no friction, maintenance-free, and stabilization time is only milliseconds. The stage is non-magnetic material, and is not affected by the magnetic field in operating.

P11.XYZ100 piezo nano-positioning stage, as a nano-displacement adjustment unit, mainly undertakes two core functions in the system:

01

Stable compensation: During the system detection process, temperature fluctuations and mechanical vibrations may cause minor drifts in the sample. Even nanometer-level drifts are sufficient to inaccurate the collected spectral data, resulting in blurred final imaging and data distortion. P11 piezo nano-positioning stage, through closed-loop control technology, actively compensates for the position drift of the sample and can stabilize the measurement point within the sub-micron or even nanometer range.

02

Precise positioning: To draw 2D or 3D thermal physical property maps, point-by-point scanning of the sample is required. Only when the step accuracy of the positioning stage is much higher than the spatial resolution of the target can the microscopic thermal structure of the sample be detected. P11 piezo nano-positioning stage moves samples or probes with nanometer-level resolution and precision, enabling high-density and high-precision scanning, ensuring data accuracy and repeatability.

Technical Data

|

Model |

P11.XYZ100S/K |

|

Active axes |

X、Y、Z |

|

Drive control |

3 driving Channels, 3 driving channels /3 sensing channels |

|

Travel range(0~120V) |

80µm/axis |

|

Max.travel range(0~150V) |

100µm/axis |

|

Sensor |

SGS/- |

|

Resolution |

3nm/0.1nm |

|

Closed-loop Linearity |

0.1%F.S./- |

|

Closed-loop repeatability |

0.05%F.S./- |

|

Pitch/yaw/roll |

<10µrad |

|

Push/pull force |

30N/5N |

|

Stiffness |

X0.25N/µm

Y0.3N/µm

Z0.2N/µm |

|

Unloaded resonant frequency |

X0.2kHz

Y0.3kHz

Z0.18kHz |

|

Unloaded step time |

20ms/0.8ms |

|

Load capacity |

0.6kg |

|

El. capacitance |

1.8μF/axis |

|

Working temperature** |

-20~80°C |

|

Material |

Steel, Al |

|

Dimensions (L×D×H) |

40mm×40mm×36.5mm |

|

Mass |

230g |

**Custom Low temperature and vacuum version available.

CoreMorrow Typical Products

In addition to the P11 piezo nano-positioning stage mentioned above, CoreMorrow also offers a diverse range of piezo nano-positioning stage product to meet the complex demands of different applications. For applications that require a larger displacement range, such as hundreds of micrometers or even millimeters, our long-stroke piezo positioning stages can provide a broader working space while maintaining nanometer-level resolution. CoreMorrow piezo nano positioning stages feature a high degree of configurability. Core parameters such as stroke, resolution, interface form and sensor type can all be customized according to the specific needs of customers, aiming to perfectly match the unique application challenges of each user.

For further details, please call +86-451-86268790, or add WeChat ID: 17051647888.

- Previous article:No more

- Next article:New Product: N81AK8T13 Piezo Optical Mount – Compact for Micro Optical Systems