Application of Piezo Nanomotion Products in Semiconductor Film Deposition!

Update time:2023-11-30 10:21:53Clicks:1277second

Note: The image is from the Internet

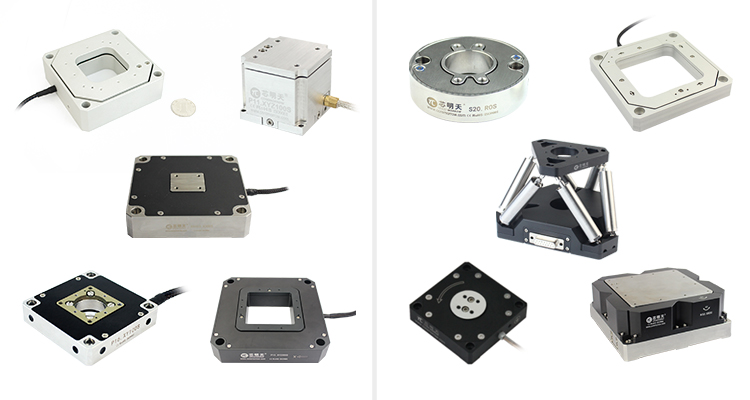

Application of CoreMorrow Piezo Nanomotion Products in Film Deposition Eequipment

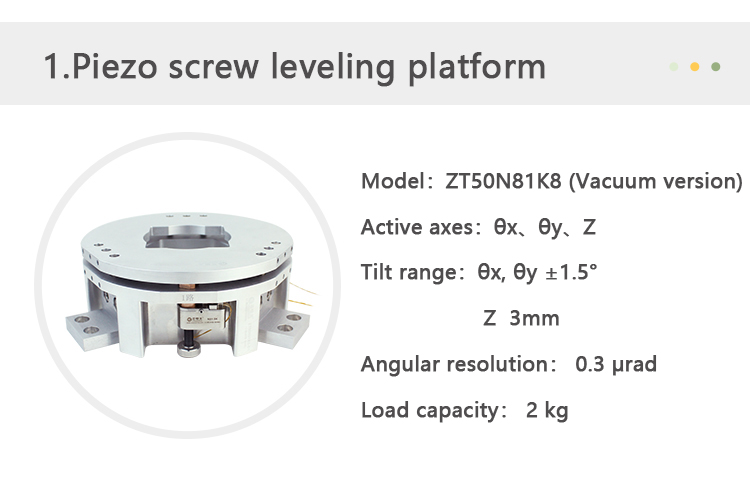

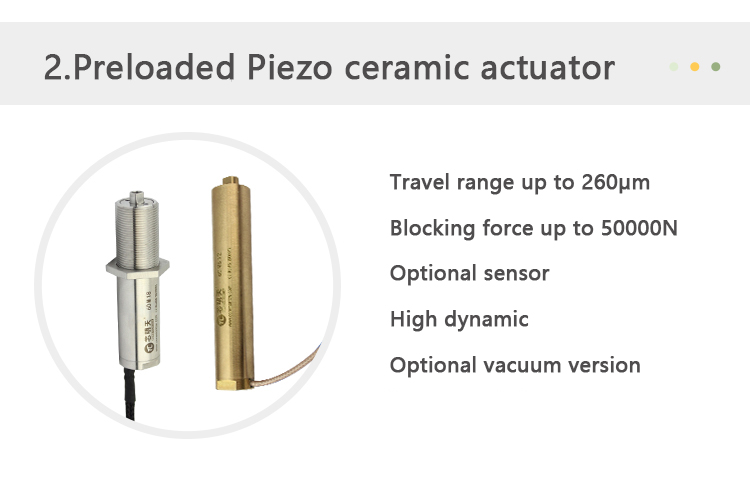

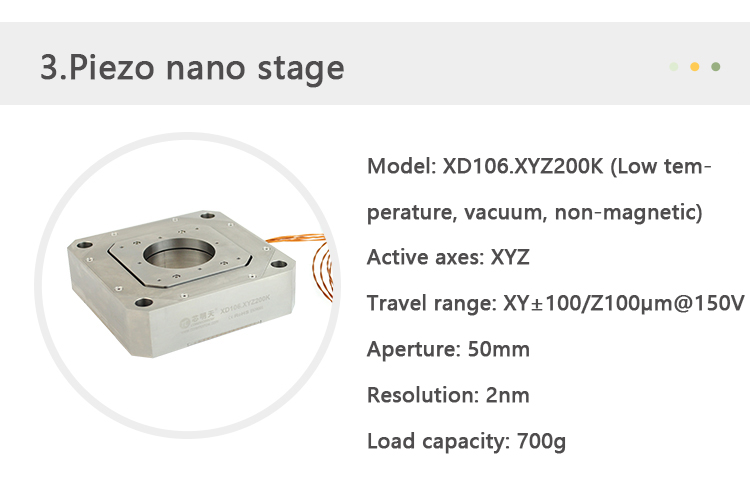

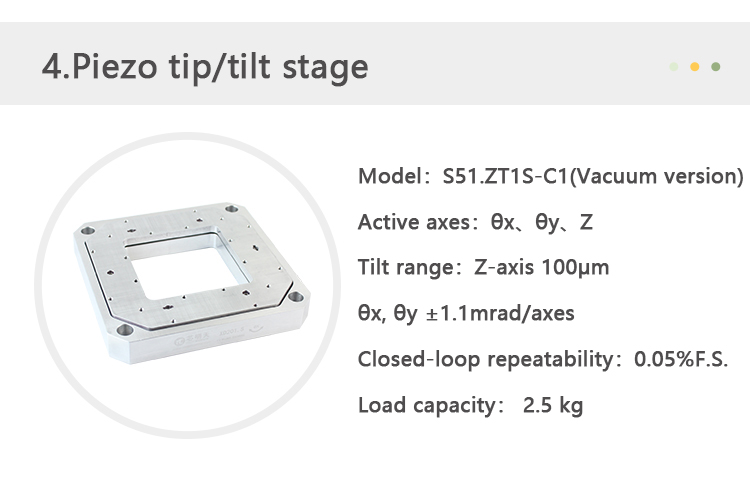

CoreMorrow Typical Models

- Previous article:Notification of Changing English Name

- Next article:Cascade Piezo Controller for Adaptive Optics, Batch Phase Modulation, and Surfac

Sweep, get the latest information on core tomorrow

Address:1F, Building I2, No.191 Xuefu Road, Nangang District, Harbin, China

Tel:0451-86268790

Copyright@ CoreMorrow Ltd. 黑ICP备16009173号-1