Innovation of Piezo Actuators Working with MFC for Precise Gas Control

Unveiling the MFC Mass Flow Controller:

The Precise Commander of Gas Flow

MFC(Mass Flow Controller) has not only the function of the MFM (Mass Flow Meter), but more importantly, it can automatically control the gas flow. Specifically, users can set the target flow value according to their actual needs, and the MFC (also often referred to as a flowmeter) will automatically maintain the flow precisely at this set value. Even in the face of system pressure fluctuations or changes in environmental temperature and other situations, it can ensure that the flow rate remains stable at the set value and will not deviate. In short, MFC is a device that can achieve steady flow function. It supports both manual flow setting and connection to a computer for automatic control. It is a commonly used device in gas steady flow.

The Working Principle of MFC Mass Flow Controller

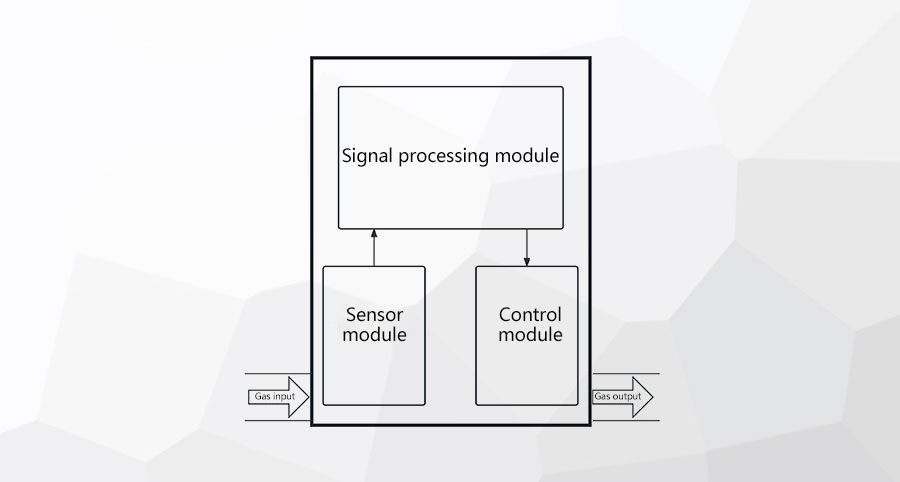

The core of the mass flow controller (MFC) is a composite system integrating sensing, signal processing and control components: When the gas flows through the channel, its sensor module measures the corresponding parameter data through the flowing medium. After the detection element converts the parameter signal into an electrical signal, the controller compares this signal with the theoretical value corresponding to the preset flow rate in real time. Through the dynamic adjustment element, the difference signal is amplified and then controlled to regulate the valve, achieving closed-loop control of the flow rate flowing through the channel, and make it equal to the set flow rate. This closed-loop control mechanism can not only calculate the actual flow rate through relevant parameter data, but also achieve the control accuracy of the set value through power feedback, ultimately achieving high-stability regulation of the gas mass flow rate.

The Stage of Mass Flow Controllers:

From Nanotechnology Labs to Industrial Giants

01

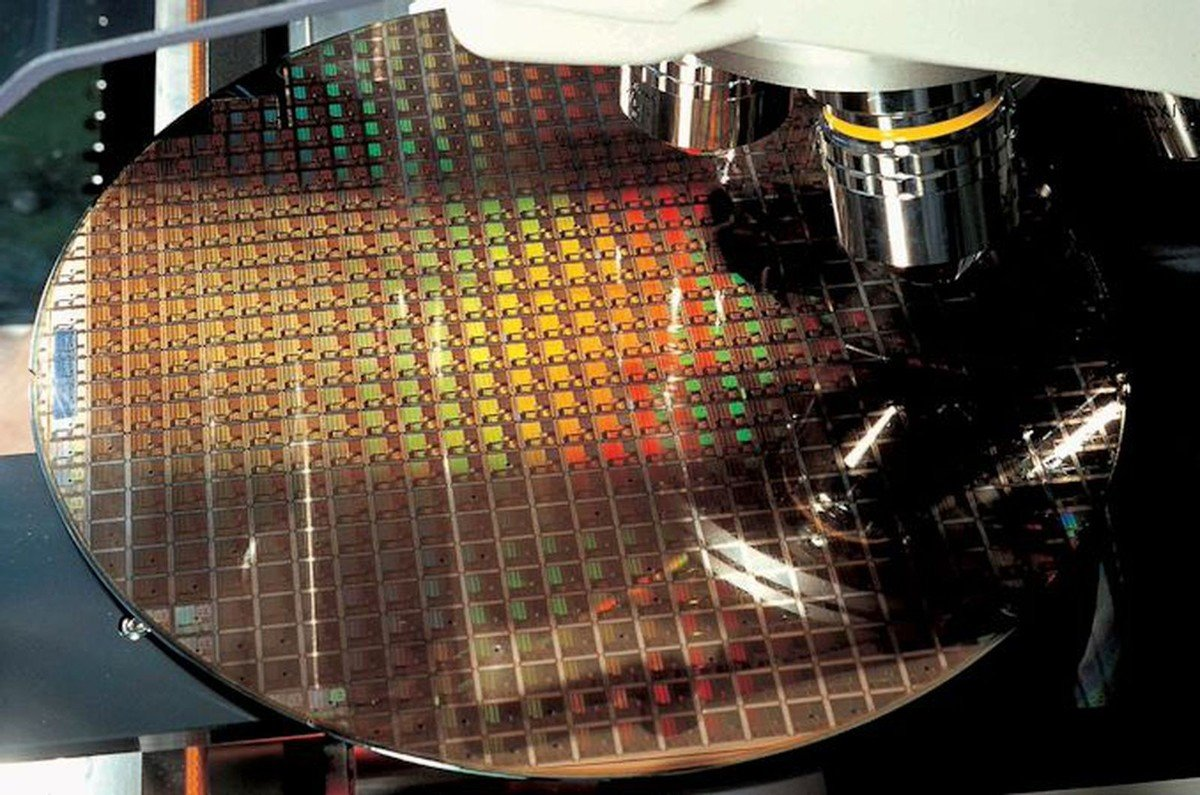

Semiconductor Manufacturing

During the wafer processing, MFC precisely controls the flow of various reactive gases, ensuring the stability of processes such as thin film deposition (CVD/PVD), etching, ion implantation, and cleaning. (The success or failure of a wafer worth tens of thousands RMB often depends on the precise control of gas flow).

02

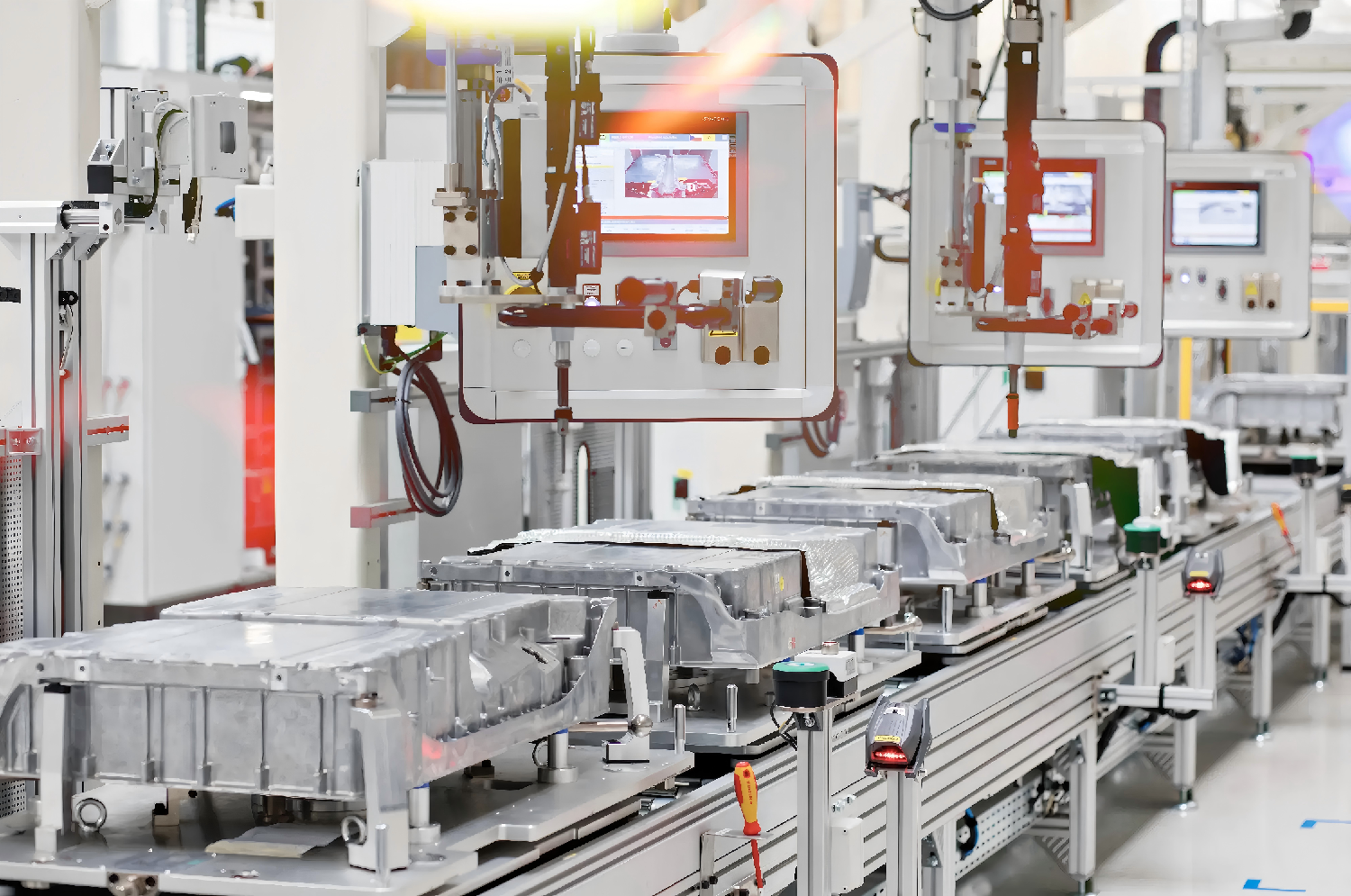

New Energy and Fuel Cells

In the production of lithium batteries, MFC controls the nitrogen purging flow to prevent moisture from entering the liquid injection workshop and ensure a dry atmosphere in the preparation process. In the production of hydrogen fuel cells, MFC precisely regulates the gas flow of the electrolytic water hydrogen production equipment and precisely controls the gas supply of the hydrogen fuel cell stack, optimizing the efficiency of electrochemical reactions.

03

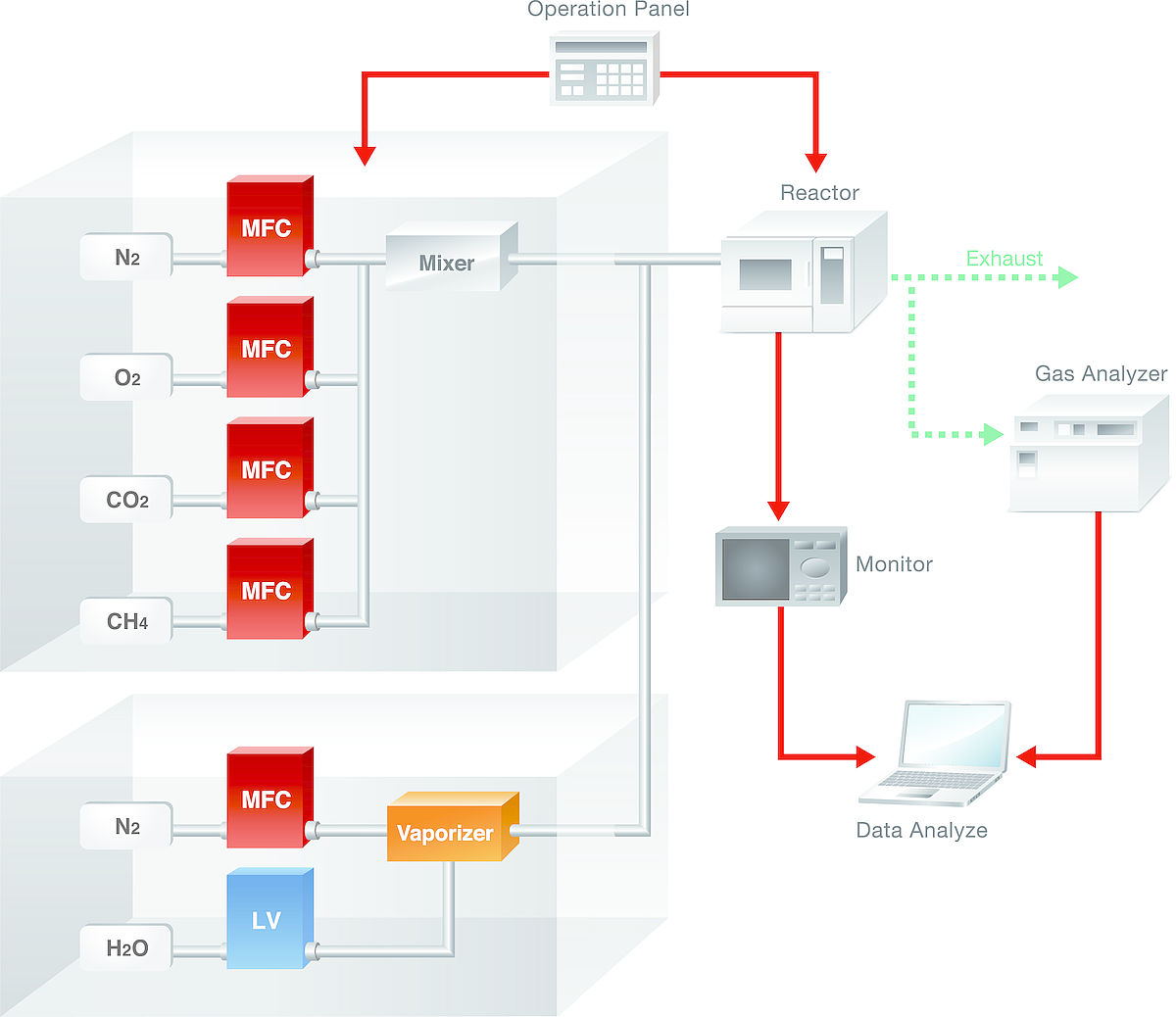

Research and Laboratory

In the basic experiments of laboratories and research institutes, MFC assists the laboratory gas mixer to achieve the dynamic mixing of multi-component gases. When conducting material research and development, for instance, in the preparation of nanomaterials such as graphene, MFC controls the flow of methane to regulate the growth rate, and so on.

As a "gas pulse regulator" for precision instruments such as gas chromatographs and mass spectrometers, MFC helps these devices control the precise gas flow rate, ensuring the accuracy of the analysis results.

(MFC achieves dynamic mixing of multi-component gases)

04

Environmental Monitoring

In environmental protection field, MFC is widely used in the measurement of air volume in air quality monitoring systems, the calibration of flow in particulate matter atmospheric samplers, and the flow control of gas analyzers and dynamic gas calibrators. They can effectively solve the problems of precise measurement and control of air volume in the process of atmospheric monitoring. For instance, MFC can monitor the concentration of VOCs during waste gas treatment and adjust the flow rate of the dilution gas to ensure the accuracy of online monitoring.

05

Bioengineering and Life Sciences

In the biotechnology industry based on life sciences, bioengineering, pharmaceuticals and medical equipment all require reliable and accurate instruments to maximize output and control processes. MFC can achieve repeatability and long-term stability, ensuring optimal gas measurement and control accuracy in R&D, bioreactors, fermenters, and medical applications. For example: During biological fermentation, MFC precisely controls the supply of oxygen and carbon dioxide during the microbial culture process, optimizing the growth efficiency of the bacteria. When mixing medical gases, MFC is responsible for adjusting the proportion of multiple gases in the anesthesia machine, ventilator and oxygen generator to ensure the safety and accuracy of inhalation concentration. During the process of microbial and cell culture, MFC controls the quantitative supply of various gases to maintain the pH value of the culture medium, etc.

In a semiconductor manufacturing workshop, an error the size of a speck of dust can lead to the scrapping of an entire wafer. In a fuel cell laboratory, a deviation of 0.1% in the hydrogen-oxygen ratio may significantly reduce the energy conversion efficiency. In the production line of medical equipment, even the slightest difference in gas flow rate may determine the life safety of patients. The core common point of these scenarios is the pursuit of the ultimate precision of the gas mass flow controller (MFC).

CoreMorrow Metal-sealed Piezo Actuator:

The Precision Revolution of MFC

Facing the extreme requirements of high-end manufacturing for the accuracy and response speed of MFC, traditional technologies have approached a bottleneck. Against this backdrop, piezoelectric ceramic technology has brought a revolutionary breakthrough to MFC.

Advantages of Piezo Ceramic Actuators:

Nanosecond-level response:Ultra-fast response speed, dozens of times faster than traditional valves;

Sub-micron positioning accuracy:Achieve nanometer-level control of valve opening, significantly enhancing the accuracy of flow regulation;

Zero power consumption maintenance:It consumes almost no electricity in a stable state, achieving remarkable energy-saving effects;

No magnetic interference:Avoids the magnetic field interference problem that traditional valves may cause.

CoreMorrow Metal-sealed Piezo Actuator

Metal-sealed piezo actuators, due to their fully sealed housing, achieve insulation from the atmospheric environment and are thus less affected by environmental humidity. They have a longer service life and higher performance, making them highly suitable for semiconductor device manufacturing equipment and optical communication equipment that require high reliability.

Characteristics

· High reliability: MTTF of 36,000 hours at 85℃ and 100V

· Precise nano-positioning

· Minimum mechanical wear

· Operating temperature: -25℃ to +85℃ or -40℃ to +150℃

· Max. blocking forc: 3600N

· Driving voltage: 0~150V

· Built-in preloading mechanism and installation accessories for easy installation into the device.

Note: MTTF (Mean Time To Failures) is the average time before failure.

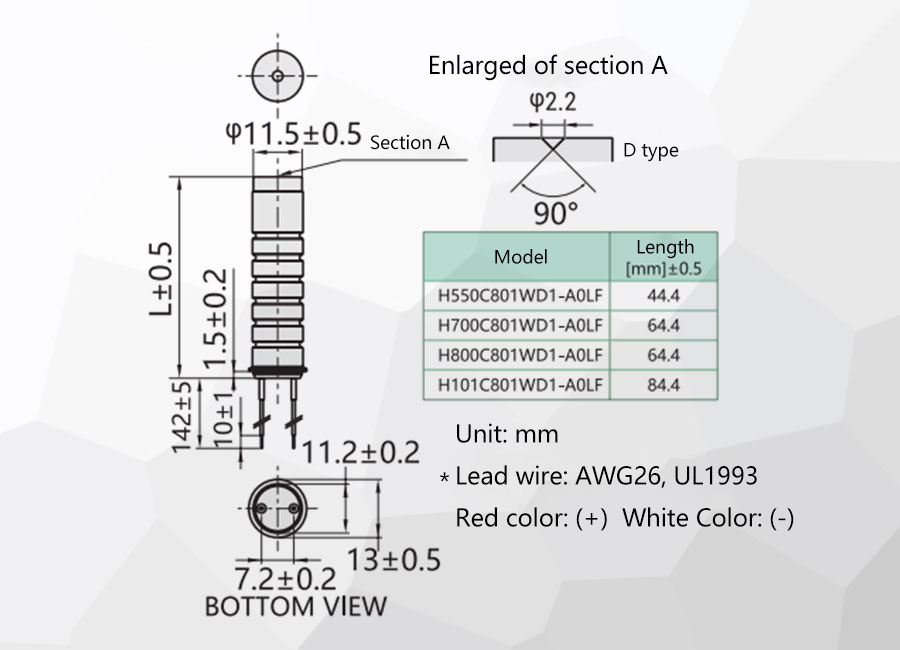

Typical Model

H550C801WD1-A0LF is one of the many models of CoreMorrow metal-sealed piezo actuators. It has 55μm stroke and 800N blocking force. Its high-standard performance makes it highly suitable for driving fluid flow control valves, and perfectly meeting the requirements of fluid flow control valves for high reliability and high precision of driving components. We have other models and custom parameter available.

Technical Data

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dimension Drawing

For further details, please call +86-451-86268790, or add WeChat ID: 17051647888.