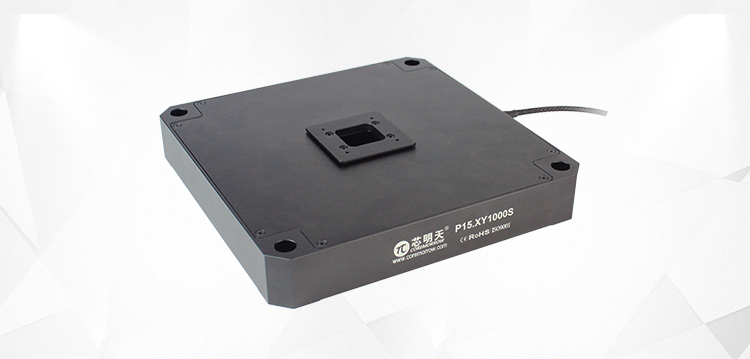

New Flexible Drive Piezo Nano Stage: Large Stroke, Nano-Precision(P15.XY1000S/K)

In the precision manufacturing and scientific research, nano-level positioning accuracy is often the key to success. To balance the requirements of large travel and high precision, CoreMorrow has launched the new P15.XY1000 piezo nano-positioning stage. It inherits the outstanding performance of the P15 and increases the single-axis travel range to 1mm, while maintaining nanometer-level precision and high stability and providing a new solution for a wider range of precision applications.

I.P15.XY1000S/K: Dual Breakthroughs in Super-Large Travel and High Precision

P15.XY1000S/K, as a new long-stroke member of the P15 series, while retaining the core advantages of the series, has made key upgrades to meet the demands of large-scale precision motion. The core highlights are concentrated in two points:

01

1mm/ Axis Super-Large Stroke: Covering a Wider Range of Applications

The P15.XY1000S/K achieves a single-axis travel of 1000μm, and the XY motion can cover a range of 1mm×1mm. This means that when handling large-sized samples, such as larger wafers and biological tissue sections, there is no need to frequently move the sample stage or adjust the optical path. This not only reduces repetitive positioning errors but also significantly improves detection and processing efficiency.

02

Nanometer-Level Precision: Not Affected by Temperature Drift

High precision is the core value of piezo nano-positioning stages. P15.XY1000S/K ensures accuracy through two major designs:

1)Built-in high-performance piezo ceramics: Fast response speed, stable output force, ensuring the smoothness and repeatability of movement;

2)Closed-loop version full-bridge design: Through a special closed-loop full-bridge connection method, it can compensate for the errors caused by environmental temperature changes in real time, avoiding the impact of temperature drift on positioning accuracy. Even in long-term continuous operation or temperature fluctuation environments, it can still stably maintain nanometer-level positioning accuracy.

II. Product Advantages

P15.XY1000S/K continues the market-proven high reliability advantages of the P15 series. These common strengths make the P15.XY1000S/K the preferred choice for many industries:

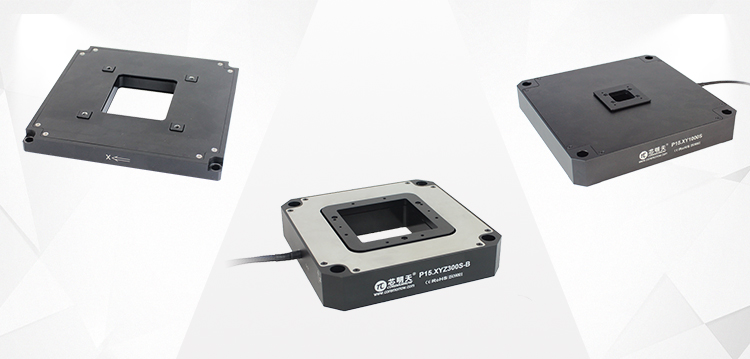

1. Frictionless, High-precision Flexible Guiding System: It dissolves the friction and wear problems of traditional mechanical guide rails. The flexible structure has no gap and no loss. It not only has a longer service life but also ensures the stability of precision after long-term use. It is suitable for high-frequency and long-term precise operations such as continuous microscopic imaging and high-frequency laser scanning.

2. Optional Closed-loop Sensor: Flexibly choose between open-loop and closed-loop versions according to requirements. The closed-loop version has higher accuracy of nanometer level.

3. High Scanning Flatness: The linearity and angular runout of the XY motion are extremely small. The FEA optimized design ensures no distorted data and no shifted image during the scanning process (such as surface inspection and 3D imaging).

4. Central Through Hole: Specifically designed for transmitted light applications, such as confocal microscopes, near-field scanning optical microscopes, etc.

5. Vacuum Version Optional: Custom version available for vacuum environment applications, breaking through the environmental limitations of conventional positioning stations.

III. Typical Applications

With 1mm super-large stroke with high stability, P15.XY1000S/K can play a key role in the following fields:

1.Semiconductor Manufacturing

In the processing and defect detection of large-size wafers, a 1mm stroke can cover a larger local area of the wafer, reduce the number of wafer movements, and improve processing efficiency and alignment accuracy.

2.Surface Inspection and 3D Imaging

For the microscopic morphology detection of large-area metal surfaces and composite material samples, P15.XY1000S/K can cover a larger area in a single scan, avoiding errors caused by multiple splicing and making the detection data more accurate.

3.Biotechnology and Micromanipulation

In bioengineering such as embryo manipulation and cell sorting, large strokes can be adapted to larger culture dishes or biochips, while nanoscale precision ensures the success rate of micro-operations (such as cell injection).

4.Laser Technology and Micro-nano Processing

In micro-processing such as laser etching and laser marking, it can help achieve larger-area microstructure processing while ensuring the consistency of the etched patterns with high precision.

5.Metrology and Precision Alignment

In high-precision measurement scenarios such as metrology and optical alignment, it can cover a larger measurement range. Combined with nanometer-level accuracy, it can quickly achieve positioning status and improve work efficiency.

(Note: Image from online resources)

(Note: Image from online resources)

IV. Technical Data

|

Model |

P15.XY1000S/K |

|

|

Active axis |

X、Y |

|

|

Drive Control |

2 driving channels, 2 sensing channels/2 driving channels |

|

|

Travel(0~120V) |

800μm |

|

|

Max. travel(0~150V) |

1000μm |

|

|

Sensor |

SGS/- |

|

|

Aperture |

25mm×25mm |

|

|

Dimension |

200mm×200mm×33mm |

|

|

Closed/open-loop resolution |

35nm/10nm |

|

|

Closed-loop linearity |

0.025%F.S./- |

|

|

Closed loop repeatability |

0.02%F.S./- |

|

|

Pitch/yaw/roll |

<20μrad |

|

|

Push/pull force |

200N/10N |

|

|

Stiffness |

0.2N/μm |

|

|

Unloaded resonant frequency |

210Hz/95Hz |

|

|

Resonant frequency |

150Hz/89Hz(@150g) |

|

|

Closed/open-loop |

120ms@50g/30ms |

|

|

Load capacity |

Horizontal |

0.15kg |

Recommended Controller

E70.D2S-L multi-channel piezo controller is a two-channel piezo controller based on the standard E70 with communication interface transformation. It can perform digital communication through serial port, USB or network port, which is very suitable for driving the P15.XY1000S/K piezo nano-positioning stage. E70.D2S-L controller is powered by DC24V, with a bandwidth of up to 10kHz. It can be controlled via analog or digital signals, and open/closed loop options are available.

For further details, please call +86-451-86268790, or add WeChat ID: 17051647888.