Application of the combination of piezo actuator and flexible hinge

Piezo actuator have the characteristics of high reliability, high resolution, high stiffness, large output, etc., and are ideal driving components for precision movement and positioning. The flexible hinge mechanical structure has the characteristics of smooth movement, no friction, no empty return, and high precision. It is suitable for forming a high-resolution, high-frequency precision motion and positioning system with piezo stack.

At the same time, the flexible hinge mechanism could also provide proper pretension, avoiding the piezo actuator from withstanding the pulling force and increasing the service life of the system. The following are some typical examples of the combination of piezo actuator driving and flexible hinge mechanism transmission.

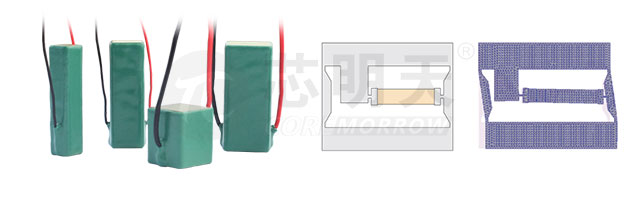

Piezo Nanopositioning Stage

The piezo nanopositioning stage adopts piezo actuator driving and flexible hinge mechanism for displacement amplification solution, which could realize precise motion of X-axis, Z-axis, XY-axis, XZ-axis, XYZ-axis and has the features of small size, zero-fricition, fast response. The displacement could be up to 1.1mm, the resolution can reach nanometer level and it has good reliability. Suitable for interference, microscopy, precision machining and other fields.

High Precision Machining

The fast tool servo system are composed of piezo actuator, flexible hinge mechanism and closed-loop sensor utilizes its own characteristics of high rigidity and high precision to drive the tool to rapidly feed in the direction of movement to realize the workpiece or structure precision machining. It has a stroke of 118μm and a resolution of nanometers.

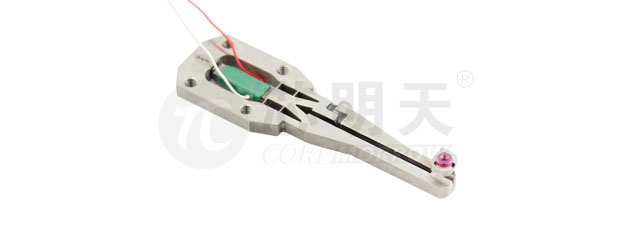

Piezo Clamp

According to the requirements of the automatic wire bonding machine, CoreMorrow designs piezo clamp, which amplifies the displacement of the piezo stack through flexible hinge mechanism, so that it can hold the gold wire and move freely. The displacement of the clamp could reach 70μm, and the response time is in the order of milliseconds.

- Previous article:CoreMorrow Piezo micro-motion stage apply for optical image stabilization

- Next article:CoreMorrow P17 series Piezo Microscopy Scanner